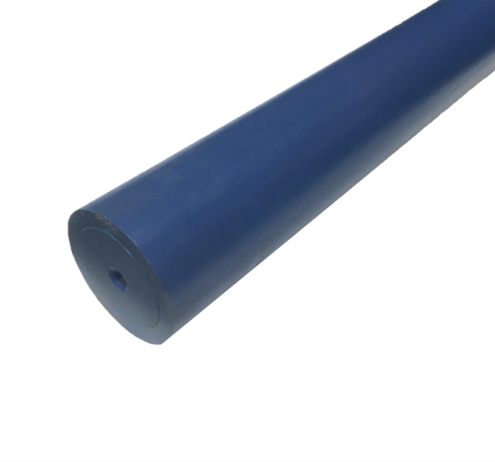

PBT Ultra Detectable

PBT Ultra Detectable Overview

What is the Material: PBT Ultra Detectable is a semi-crystalline material filled with a multi detectable filler.

Key Material Features: This material is beneficial in applications requiring increased food safety, while providing many benefits of other PBT materials including impact resistance, chemicals resistance, wear resistance, low coefficient of friction, and low moisture absorption.

Other Considerations: The filler makes the material detectable using x-ray imaging, metal detection, and by optical scanners. This material has higher impact resistance than PET.

Physical

| Property | Value | Typical ASTM Test |

|---|---|---|

| Chemical Designation | (PBT) Polybutylene terephthalate | |

| Trade Names (®, ™) | HYDEX 4101 UD Blue | |

| Filler | Detectable Filler | |

| Color | Blue | |

| Density (g/cm^3) | 1.59 | D 792 |

Mechanical

| Property | Value | Typical ASTM Test |

|---|---|---|

| Modulus of Elasticity (Tensile Test) (psi) | 550000 | D 638 |

| Tensile Strength at Yield (psi) | 9300 | D 638 |

| Elongation at Break (%) | 3.53 | D 638 |

| Flexural Strength (psi) | 15250 | D 790 |

| Modulus of Elasticity (Flexural Test) (psi) | 556150 | D 790 |

| Compression Strength: 10% Strain (psi) | 13760 | D 695 |

| Compression Strength: 1% Strain (psi) | 3200 | D 695 |

| Compression Modulus (psi) | 346360 | D 695 |

| Impact Strength (Izod) (ft-lbs/in) | 0.58 | D 256 |

| Hardness (M) | 92 | D 785 |

Thermal

| Property | Value | Typical ASTM Test |

|---|---|---|

| Melting Point (°F) | 437 | D 3418 |

| Deflection Temperature (°F) (66 psi) | 393 | D 648 |

| Deflection Temperature (°F) (264 psi) | 275 | D 648 |

| Service Temperature Continuous (°F) | 221 | |

| Thermal Expansion (CLTE) (in/in/°F) | 4.05E-5 | D 696 |

Other

| Property | Value | Typical ASTM Test |

|---|---|---|

| Moisture Absorption (%) (24 Hours) | 0.2 | D 570 |

The data stated are typical values intended for reference and comparison purposes only. The data should not be used as a basis for design specifications or quality control. The information is provided as a guide to the best of our knowledge and given without obligation or liability. Testing under individual application circumstances is recommended.